Carbon nanotubes: synthesis, properties and engineering applications

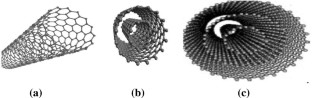

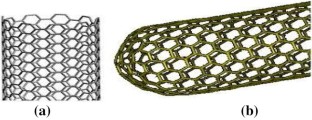

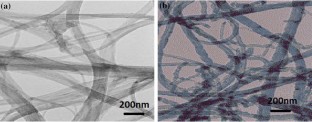

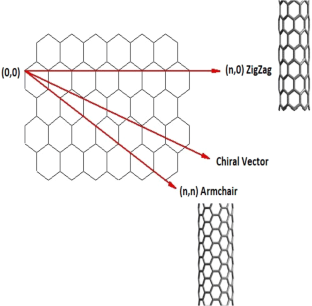

Carbon nanotubes (CNT) represent one of the most unique materials in the field of nanotechnology. CNT are the allotrope of carbon having sp 2 hybridization. CNT are considered to be rolled-up graphene with a nanostructure that can have a length to diameter ratio greater than 1,000,000. CNT can be single-, double-, and multi-walled. CNT have unique mechanical, electrical, and optical properties, all of which have been extensively studied. The novel properties of CNT are their light weight, small size with a high aspect ratio, good tensile strength, and good conducting characteristics, which make them useful for various applications. The present review is focused on the structure, properties, toxicity, synthesis methods, growth mechanism and their applications. Techniques that have been developed to synthesize CNT in sizeable quantities, including arc discharge, laser ablation, chemical vapor deposition, etc., have been explained. The toxic effect of CNT is also presented in a summarized form. Recent CNT applications showing a very promising glimpse into the future of CNT in nanotechnology such as optics, electronics, sensing, mechanical, electrical, storage, and other fields of materials science are presented in the review.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

History of Carbon Nanotubes

Chapter © 2022

History of Carbon Nanotubes

Chapter © 2022

Carbon Nanotubes: General Introduction

Chapter © 2022

References

- Dai H (2003) Carbon nanotubes: synthesis, integration and properties acc. Chem Res 35:1035–1044 Google Scholar

- Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354:56–58 Google Scholar

- Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363:603–605 Google Scholar

- Bethune DS et al (1993) Cobalt- catalyzed growth of carbon nanotubes with single-atomic-layer walls. Nature 363:605–607 Google Scholar

- Esumi K et al (1995) Chemical treatment of carbon nanotubes. Carbon 34(2):279–281 Google Scholar

- Ni W et al (2006) Fabrication and properties of carbon nanotubes and poly (vinyl alcohol) composites. J Macromol Sci B 45:659–664 Google Scholar

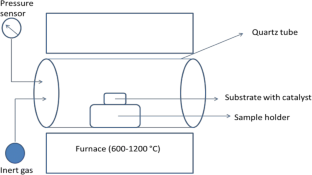

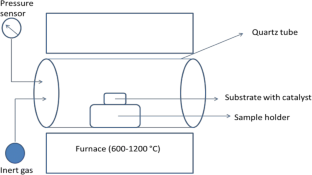

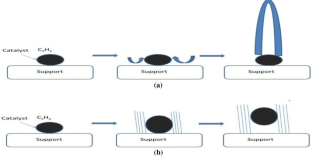

- Kumar M, Ando Y (2010) Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production. J Nanosci Nanotechnol 10:3739–3758 Google Scholar

- Prasek J et al (2011) Methods for carbon nanotubes synthesis-review. J Mater Chem 21:15872–15884 Google Scholar

- Chavan R et al (2012) A review: carbon nanotubes. Int J Pharm Sci 13:125–134 Google Scholar

- Eatmadi A et al (2014) Carbon nanotubes: properties, synthesis, purification, and medical applications. Nanoscale Res Lett 9:393 Google Scholar

- Sharma R et al (2015) Synthesis of carbon nanotubes by arc-discharge and chemical vapor deposition method with analysis of its morphology, dispersion and functionalization characteristics. Cogent Eng 2:1095017 Google Scholar

- Lan Y et al (2011) Physics and applications of aligned carbon nanotubes. Adv Phys. https://doi.org/10.1080/00018732.2011.599963Google Scholar

- Hone J et al (2002) Thermal properties of carbon nanotubes and nanotube-based materials. Appl Phys A. https://doi.org/10.1007/s003390201277Google Scholar

- Meyyappan M et al (2003) Carbon nanotube growth by PECVD: a review. Plasma Sources Sci Tech 12:205–216 Google Scholar

- Ibrahim SK (2013) Carbon nanotubes–properties and applications: a review. Carbon Lett. https://doi.org/10.5714/CL.2013.14.3.131

- Ajayan PM, Zhou Z (2001) Applications of Carbon nanotubes. Appl Phys 80:391–425 Google Scholar

- Robertson J (2004) Realistic applications of CNTs. Mater Today 7:46–52 Google Scholar

- Trojanowicz M (2006) Analytical applications of carbon nanotubes: a review. Trends Anal Chem 25(5):480–489 Google Scholar

- Hirlekar R et al (2009) Carbon nanotubes and its applications: a review. Asian J Pharm Clin Res 2(4):17–27 Google Scholar

- Schnorr JM, Swager TM (2010) Emerging applications of carbon nanotubes. Chem Mater. https://doi.org/10.1021/cm102406hGoogle Scholar

- Liu C, Cheng HM (2013) Carbon nanotubes: controlled growth and application. Mater Today 16:19–28 Google Scholar

- Nessim GD (2010) Properties, synthesis and growth mechanism of carbon nanotubes with special focus on thermal chemical vapor deposition. Nanoscale. https://doi.org/10.1039/b9nr00427kGoogle Scholar

- Jariwala D (2013) Carbon nanomaterials for electronics, optoelectronics, photovoltics and sensing. Chem Soc Rev. https://doi.org/10.1039/c2cs35335kGoogle Scholar

- Belin T, Epron F (2005) Characterization methods of carbon nanotubes: a review. Mater Sci Eng B. https://doi.org/10.1016/j.mseb.2005.02.046Google Scholar

- Aqel A et al (2012) A Carbon nanotubes, science and technology part (I) structure, synthesis and characterization. Arab J Chem. https://doi.org/10.1016/j.arabjc.2010.08.022Google Scholar

- Thostenson ET et al (2001) Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol 61:1899–1912 Google Scholar

- Kuzmany H et al (2004) Functionalization of carbon nanotubes. Synthetic Metals. https://doi.org/10.1016/j.synthmet.2003.08.018Google Scholar

- Shah KA, Tali BA (2016) Synthesis of carbon nanotubes by catalytic chemical vapour deposition: A review on carbon sources, catalysts and substrates. Mater Sci Semicond Process. https://doi.org/10.1016/j.mssp.2015.08.013Google Scholar

- Fan Z, Advani SG (2007) Rheology of multiwall carbon nanotube suspensions. J Rheol. https://doi.org/10.1122/1.2736424Google Scholar

- Bhatt A et al (2016) Carbon nanotubes: a promising carrier for drug delivery and targeting. Nano Architecton Smart Deliv Drug Target. https://doi.org/10.1016/B978-0-323-47347-7.00017-3Google Scholar

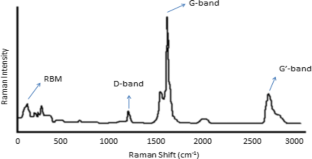

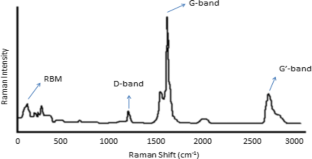

- Dresselhaus MS et al (2005) Raman spectroscopy of carbon nanotubes. Phys Rep. https://doi.org/10.1016/j.physrep.2004.10.006Google Scholar

- Khare R, Bose S (2005) Carbon nanotube based composites—a review. J Miner Mater Charact Eng 4:31–46 Google Scholar

- Lekawa-Raus A et al (2014) Electrical properties of carbon nanotube based fibers and their future use in electrical wiring. Adv Funct Mater. https://doi.org/10.1002/adfm.201303716Google Scholar

- Bernholc J et al (2002) Mechanical and electrical properties of nanotubes. Annu Rev Mater Res 32:347–375. https://doi.org/10.1146/annurev.matsci.32.112601.134925Google Scholar

- Tang QY et al (2010) R Study of the dispersion and electrical properties of carbon nanotubes treated by surfactants in dimethyacetamide. J Nanosci Nanotechnol. https://doi.org/10.1166/jnn.2010.2224Google Scholar

- Ibrahim SK (2013) Carbon nanotubes-properties and applications: a review. Carbon Lett. https://doi.org/10.5714/cl.2013.14.3.131Google Scholar

- Ruoff RS, Lorents DC (1995) Mechanical and thermal properties of carbon nanotubes. Carbon 33(7):925–930 Google Scholar

- Eastman JA et al (2004) Thermal transport in nanofluids. Annu Rev Mater Res 34:219–246 Google Scholar

- Yu MF et al (2000) Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett 84:552–555 Google Scholar

- Jishi RA et al (1993) Phonon modes in carbon nanotubes. Chem Phys Lett 209:77–82 Google Scholar

- Singh R, Gupta SM (2016) Introduction to nanotechnology. OXFORD University Press, India Google Scholar

- Hiura H et al (1993) Raman studies of carbon nanotubes. Chem Phys Lett 202:509–512 Google Scholar

- Ghasempour R, Narei H (2018) CNT basics and characteristics. In: Rafiee R (ed) Carbon nanotube-reinforced polymers. Elsevier, Amsterdam, pp 1–24 Google Scholar

- Maultzsch J (2004). Vibrational properties of carbon nanotubes and graphite. Doctoral thesis. https://doi.org/10.14279/depositonce-967

- Hur J, Stuart SJ (2017) Raman intensity and vibrational modes of armchair CNTs. Chem Phys Lett. https://doi.org/10.1016/j.cplett.2017.04.078Google Scholar

- Hodkiewicz J (2010) Characterizing carbon materials with Raman spectroscopy. Thermo Fisher Scientific, Madison Google Scholar

- Costa S et al (2008) Characterization of carbon nanotubes by Raman spectroscopy. Mater Sci Pol 26(2):433–441 Google Scholar

- Lei XW et al (2011) Radial breathing mode of carbon nanotubes subjected to axial pressure. Nanoscale Res Lett. https://doi.org/10.1186/1556-276x-6-492Google Scholar

- Moura LG et al (2017) The double-resonance Raman spectra in single-chirality (n, m) carbon nanotubes. Carbon. https://doi.org/10.1016/j.carbon.2017.02.048Google Scholar

- Andersson CH (2011) Chemistry of carbon nanostructures. Uppsala University, Physical Organic Chemistry, Uppsala Google Scholar

- Tasis D et al (2006) Chemistry of carbon nanotubes. Chem Rev. https://doi.org/10.1021/cr050569oGoogle Scholar

- Adamska M, Narkiewicz U (2017) Fluorination of carbon nanotubes—a review. J Fluor. https://doi.org/10.1016/j.jfluchem.2017.06.018Google Scholar

- Hirsch A (2002) Functionalization of single-walled carbon nanotubes. Angew Chem Int Ed 41(11):1853–1859 Google Scholar

- Melchionna M, Prato M (2013) Functionalizing Carbon Nanotubes: An Indispensable Step towards Applications. ECS J Solid State Sci Technol. https://doi.org/10.1149/2.0083jssGoogle Scholar

- Ewels CP, Glerup M (2005) Nitrogen doping in carbon nanotubes. J Nanosci Nanotechnol. https://doi.org/10.1166/jnn.2005.304Google Scholar

- Terrones M et al (2008) Doped carbon nanotubes: synthesis, characterization and applications. Appl Phys 111:531–566 Google Scholar

- Souza Filho AG, Terrones M (2009) Properties and applications of doped carbon nanotubes. B-C-N nanotubes and related nanostructures. Springer, New York, pp 223–269 Google Scholar

- Paraknowitsch JP, Thomas A (2013) Doping carbons beyond nitrogen: an overview of advanced heteroatom doped carbons with boron, sulphur and phosphorus for energy applications. Energy Environ Sci. https://doi.org/10.1039/c3ee41444bGoogle Scholar

- Mittal V (2011) Surface modification of nanotube fillers. Carbon nanotubes surface modifications: an overview, 1st edn. Wiley, New York, pp 1–23 Google Scholar

- Jeon IY et al (2011) Carbon nanotubes-polymer nanocomposite. In: Yellampali (ed) Functionalization of carbon nanotubes, pp 91–110

- Wepasnick KA et al (2010) Chemical and structural characterization of carbon nanotube surfaces. Anal Bioanal Chem 10:10. https://doi.org/10.1007/s00216-009-3332-5Google Scholar

- Khalid P et al (2016) Toxicology of carbon nanotubes—a review. Int J Appl Eng Res 11(1):148–157 Google Scholar

- Bellucci S (2009) Carbon nanotubes toxicity. In: Bellucci S (ed) Nanoparticles and nanodevices in biological applications. The INFN lectures - vol I, vol 4. Springer, Berlin, Heidelberg, pp 47–67 Google Scholar

- Kiang CH et al (1995) Carbon nanotubes with single layer walls. Carbon 33(7):903–914 Google Scholar

- Mintmire JW, White CT (1995) Electronic and structural properties of carbon nanotubes. Carbon 33(7):893–902 Google Scholar

- Kaushik BK, Majumder MK (2015) Carbon nanotube based VLSI interconnects analysis and design. Chapter-2 carbon nanotube: properties and applications. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2047-3_2Google Scholar

- Charlier JC et al (1996) Structural and electronic properties of pentagon-heptagon pair defects in carbon nanotubes. Phys Rev B 53(16):108–113 Google Scholar

- He H, Pan B (2009) Studies on structural effects in carbon nanotubes. Front Phys China. https://doi.org/10.1007/s11467-009-0021-yGoogle Scholar

- Sharma K et al (2012) Effect of multiple stone-wales and vacancy defects on the mechanical behavior of carbon nanotubes using molecular dynamics. Proced Eng 38:3373–3380 Google Scholar

- Ebbesen TW, Takada T (1995) Topological and sp3 defect structures in nanotubes. Carbon 33(7):973–978 Google Scholar

- Kroto HW et al (1993) Buckminster fullerene. Nature 318:162–163 Google Scholar

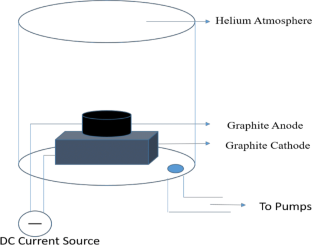

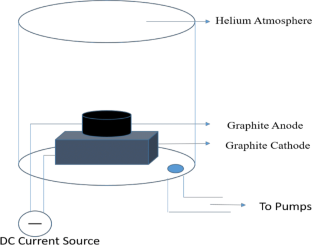

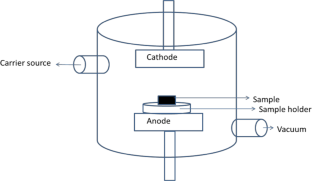

- Arora N, Sharma NN (2014) Arc discharge synthesis of carbon nanotubes: comprehensive review. Diam Relat Mater 50:135–150 Google Scholar

- Purohit R et al (2014) Carbon nanotubes and their growth methods. Proced Mater Sci 6:716–728 Google Scholar

- Farhat S, Scott CD (2006) Review of the arc process modeling for fullerene and nanotube production. J Nanosci Nanotechnol 6:1189–1210 Google Scholar

- Ando Y (2010) Carbon nanotube: the inside story. J Nanosci Nanotechnol. https://doi.org/10.1166/jnn.2010.2017Google Scholar

- Krzystof K et al (2010) Carbon and oxide nanostructures, advanced structured materials. In: Yahya N (ed) Synthesis of carbon nanostructures by CVD method. Springer, Berlin, pp 23–49. https://doi.org/10.1007/8611_2010_12Google Scholar

- Gang X et al (2007) Analysis of the carbon nano-structures formation in liquid arcing. Plasma Sci Technol 9(6):770–773 Google Scholar

- Varshney K (2014) Carbon nanotubes: a review on synthesis, properties and applications. Int J Eng Res General Sci 2(4):660–677 Google Scholar

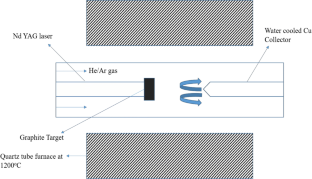

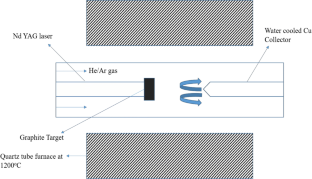

- Arepalli S (2004) Laser Ablation process for single-walled carbon nanotube production. J Nanosci Nanotechnol. https://doi.org/10.1166/jnn.2004.072Google Scholar

- Scott CD et al (2001) Growth mechanisms for single-wall carbon nanotubes in a laser-ablation process. Appl Phys A. https://doi.org/10.1007/s003390100761Google Scholar

- Arepalli S et al (2001) Production and measurements of individual single-wall nanotubes and small ropes of carbon. Appl Phys Lett. https://doi.org/10.1063/1.1352659Google Scholar

- Sinnott SB, Andrews R (2001) Carbon nanotubes: synthesis, properties, and applications. Crit Rev Solid State Mater Sci 10:10. https://doi.org/10.1080/20014091104189Google Scholar

- Braidy N et al (2002) A Single-wall carbon nanotubes synthesis by means of UV laser vaporization. Chem Phys Lett 354:88–92 Google Scholar

- Ding RG et al (2001) A Recent advances in the preparation and utilization of carbon nanotubes for hydrogen storage. J Nanosci Nanotechnol. https://doi.org/10.1166/jnn.2001.012Google Scholar

- Yudasaka M et al (1999) Formation of single-wall carbon nanotubes: comparison of CO2 laser ablation and Nd:YAG laser ablation. J Phys Chem B. https://doi.org/10.1021/jp990072gGoogle Scholar

- Walker PL et al (1959) Carbon formation from carbon monoxide-hydrogen mixtures over iron catalysis I. Properties of carbon formed. J Phys Chem 63:133–140 Google Scholar

- Jose Yacaman M et al (1993) Catalytic growth of carbon microtubules with fullerene structure. Appl Phys Lett. https://doi.org/10.1063/1.108857Google Scholar

- Tempel H et al (2010) Ink jet printing of ferritin as method for selective catalyst patterning and growth of multiwalled carbon nanotubes. Mater Chem Phys. https://doi.org/10.1016/j.matchemphyw01.-029Google Scholar

- Popov VN (2004) Carbon nanotubes: properties and applications. Mater Sci Eng. https://doi.org/10.1016/j.mser.3003.10.001Google Scholar

- Yang F et al (2017) Water-assisted preparation of high-purity semiconducting (14,4) carbon nanotubes. ACS Nano. https://doi.org/10.1021/1csnano.6b0689Google Scholar

- Ding EX et al (2017) Highly conductive and transparent single-walled carbon nanotube thin films from ethanol by floating catalyst chemical vapor deposition. Nanoscale. https://doi.org/10.1039/c7nr05554dGoogle Scholar

- Zhou W, Ding L, Liu J (2009) Role of catalysts in the surface synthesis of single-walled carbon nanotubes. Nano Res. https://doi.org/10.1007/s12274-009-9068-xGoogle Scholar

- Nasibulin AG et al (2005) A novel aerosol method for single walled carbon nanotube synthesis. Chem Phys Lett. https://doi.org/10.1016/j.cplett.2004.12.040Google Scholar

- Ahmad S et al (2005) Systematic investigation of the catalyst composition effects on single-walled carbon nanotubes synthesis in floating-catalyst CVD. Carbon. https://doi.org/10.1016/j.carbon.2019.04.026Google Scholar

- Agrez A et al (2010) Catalytic CVD Synthesis of carbon nanotubes: towards high yield and low temperature growth. Materials. https://doi.org/10.3390/ma3114871Google Scholar

- Flahaut E et al (1999) Synthesis of single-walled carbon nanotubes using binary Fe Co, Ni/alloy nanoparticles prepared in situ by the reduction of oxide solid solutions. Chem Phys Lett 300:236–242 Google Scholar

- Li WZ et al (1996) Large-scale synthesis of aligned carbon nanotubes. Science 274:1701–1703 Google Scholar

- Terrones M et al (1997) Controlled production of aligned-nanotube bundles. Nature 388:52–55 Google Scholar

- Pan ZW et al (1998) Very long carbon nanotubes. Nature 394:631–632 Google Scholar

- Li J et al (1999) Highly ordered carbon nanotube arrays for electronics applications. Appl Phys Lett 75:367–369 Google Scholar

- Andrews R et al (1999) Continuous production of aligned carbon nanotubes: a step closer to commercial realization. Chem Phys Lett 303:467–474 Google Scholar

- Wei BQ et al (2002) Organized assembly of carbon nanotubes. Nature 416:495–496 Google Scholar

- Liao Y et al (2018) Tuning geometry of SWCNTs by CO2 in floating catalyst CVD for high-performance transparent conductive films. Adv Mater Interfaces. https://doi.org/10.1002/admi.201801209Google Scholar

- Hussain A et al (2018) Floating catalyst CVD synthesis of single walled carbon nanotubes from ethylene for high performance transparent electrodes. Nanoscale. https://doi.org/10.1039/c8nr00716kGoogle Scholar

- Okada T et al (2019) Low-temperature synthesis of single-walled carbon nanotubes with Co catalysts via alcohol catalytic chemical vapor deposition under high vacuum. Mater Today Commun. https://doi.org/10.1016/j.mtcomm.2018.12.018Google Scholar

- Eveleens CA, Stephan I, Page AJ (2019) How does acetonitrile modulate single-walled carbon nanotube diameter during CVD growth? Carbon. https://doi.org/10.1016/j.carbon.2019.02.027Google Scholar

- Eveleens CA, Page AJ (2019) Catalyst and etchant dependent mechanisms of single-walled carbon nanotube nucleation during chemical vapor deposition. J Phys Chem C. https://doi.org/10.1021/acs.jpcc.8b12276Google Scholar

- Romanenko AI et al (2018) temperature dependence of electrical conductivity and thermoelectric power of transparent SWCNT films obtained by aerosol CVD synthesis. Phys Status Solidi B 10:10. https://doi.org/10.1002/pssb.201700642Google Scholar

- Chen M et al (2002) Preparation of high yield multi-walled carbon nanotubes by microwave plasma chemical vapor deposition at low temperature. J Mater Sci 37:3561–3567 Google Scholar

- Huang ZP, Wang DZ, Wen JG, Sennett M, Gibson H, Ren ZF (2002) Effect of nickel, iron and cobalt on growth of aligned carbon nanotubes. Appl Phys A Mater Sci Process 74(3):387–391. https://doi.org/10.1007/s003390101186Google Scholar

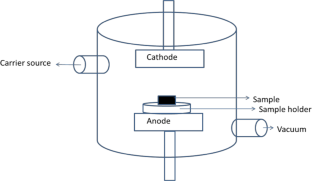

- Ren ZF et al (1998) Synthesis of large arrays of well-aligned carbon nanotubes on glass. Science. https://doi.org/10.1126/science.282.5391.1105Google Scholar

- Teo KBK et al (2003) Plasma enhanced chemical vapour deposition carbon nanotubes/nanofibres—how uniform do they grow? Nanotechnology 14:204–211 Google Scholar

- Boskovic BO et al (2002) Large-area synthesis of carbon nanofibers at room temperature. Nat Mater. https://doi.org/10.1038/nmat755Google Scholar

- Minea TM et al (2004) Room temperature synthesis of carbon nanofibers containing nitrogen by plasma-enhanced chemical vapor deposition. Appl Phys Lett. https://doi.org/10.1063/1.1781352Google Scholar

- Hofmann S et al (2003) Low-temperature growth of carbon nanotubes by plasma-enhanced chemical vapor deposition. Appl Phys Lett. https://doi.org/10.1063/1.1589187Google Scholar

- Hofmann S et al (2003) Direct growth of aligned carbon nanotube field emitter arrays onto plastic substrates. Appl Phys Lett. https://doi.org/10.1063/1.1630167Google Scholar

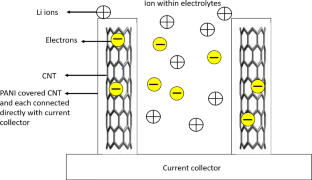

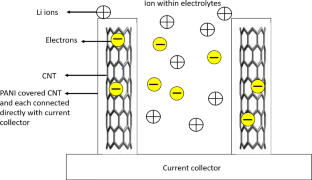

- Hussain S et al (2018) Plasma synthesis of polyaniline enrobed carbon nanotubes for electrochemical applications. Electrochim Acta. https://doi.org/10.1016/j.electacta.2018.02.112Google Scholar

- Journet C et al (1997) Large-scale production of single-walled carbon nanotubes by the electric-arc technique. Nature 388:756–758 Google Scholar

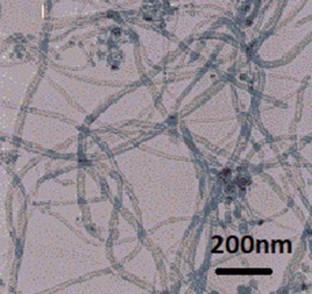

- Yasuda A, Kawase N, Mizutani W (2002) Carbon nanotube formation mechanism based on in situ TEM observation. J Phys Chem B 106:13294–13298. https://doi.org/10.1021/jp020977lGoogle Scholar

- Saito Y et al (1995) Extrusion of single-wall carbon nanotubes via formation of small particles condensed near arc evaporation source. Chem Phys Lett 236:419–426 Google Scholar

- Kurt R, Bonard JM, Karimi A (2001) Structure and field emission properties of decorated CyN nanotubes tuned by diameter variations. Thin Solid Films 398–399:193–198 Google Scholar

- Wang X et al (2002) Controllable growth, structure, and low field emission of well-aligned CNx nanotubes. J Phys Chem B. https://doi.org/10.1021/jp013007rGoogle Scholar

- Saito Y, Uemura S, Hamaguchi K (1998) Cathode ray tube lighting elements with carbon nanotube field emitters. Jpn J Appl Phys 37:L346–L348 Google Scholar

- Zhu W et al (1999) Large current density from carbon nanotubes field emitters. Appl Phys Lett. https://doi.org/10.1063/1.124541Google Scholar

- Bonard JM, Stockli T, Noury O, Chatelain A (2001) Field emission from cylindrical carbon nanotube cathodes: possibilities for luminescent tubes. Appl Phys Lett. https://doi.org/10.1063/1.1367903Google Scholar

- Chung KJ et al (2008) Improvement of lighting uniformity and phosphor life in field emission lamps using carbon nanocoils. J Nanomater. https://doi.org/10.1155/2015/373549Google Scholar

- Murakami H, Hirakawa M, Tanaka C, Yamakawa H (2000) Field emission from well-aligned, patterned, carbon nanotube emitters. Appl Phys Lett. https://doi.org/10.1063/1.126164Google Scholar

- Saito Y, Uemura S (2000) Field emission from carbon nanotubes and its application to electron sources. Carbon 38:169–182 Google Scholar

- Ericson LM et al (2004) Macroscopic, neat, single-walled Carbon nanotube fibers. Science. https://doi.org/10.1126/science.1101398Google Scholar

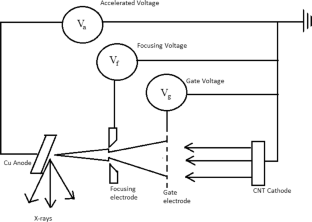

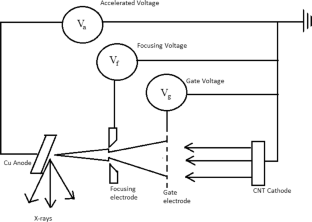

- Surgie H et al (2001) Carbon nanotubes as electron source in an x-ray tube. Appl Phys Lett. https://doi.org/10.1063/1.1367278Google Scholar

- Hwang RJ et al (2012) Carbon nanotube electron emitter for X-ray imaging. Materials. https://doi.org/10.3390/ma5112353Google Scholar

- Teo KBK et al (2005) Carbon nanotubes as cold cathodes. Nature. https://doi.org/10.1038/437968aGoogle Scholar

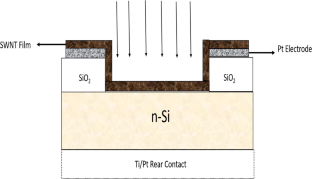

- Hasobe T, Fukuzumi S, Kamat PV (2006) Stacked-cup carbon nanotubes for photoelectrochemical solar cells. Angew Chem Int Ed. https://doi.org/10.1002/anie.200502815Google Scholar

- Kempa K et al (2003) Photonics crystals based on periodic arrays of aligned carbon nanotubes. Nano Letters. https://doi.org/10.1021/n10258271Google Scholar

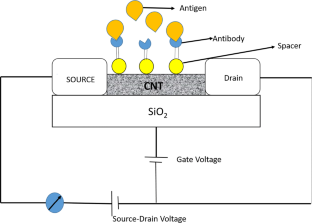

- Wang J et al (2004) Ultrasensitive electrical biosensing of proteins and DNA: carbon-nanotube derived amplification of the recognition and transduction events. J Am Chem Soc. https://doi.org/10.1021/ja031723wGoogle Scholar

- Wang X et al (2005) Improved super lensing in two-dimensional photonic crystals with a basis. Appl Phys Lett. https://doi.org/10.1063/1.1863413Google Scholar

- Kempa K et al (2007) Carbon nanotubes as optical antennae. Adv Mater. https://doi.org/10.1002/adma.200601187Google Scholar

- Cui K, Maruyama S (2016) Carbon nanotubes silicon solar cells. IEEE Nanotechnol Mag. https://doi.org/10.1109/mnano.2015.2506318Google Scholar

- Wang F et al (2014) Fabrication of single-walled carbon nanotube/Si heterojunction solar cells with high photovoltaic performance. ACS Photonics. https://doi.org/10.1021/ph400133kGoogle Scholar

- Li Z et al (2013) Solar cells with graphene and carbon nanotubes on silicon. J Exp Nanosci. https://doi.org/10.1080/17458080.2011.572191Google Scholar

- Baughman RH, Zakhidov AA, de Heer WA (2002) Carbon nanotubes-the route towards applications. Science 10:10. https://doi.org/10.1126/science.1060928Google Scholar

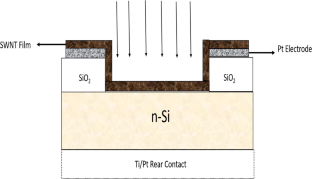

- Gooding JJ et al (2003) Protien electrochemistry using aligned carbon nanotube arrays. J Am Chem Soc. https://doi.org/10.1021/ja035722fGoogle Scholar

- Nugent JM, Santhanam KSV, Rubio A, Ajayan PM (2001) Fast electron transfer kinetics on multiwalled carbon nanotube microbundle electrodes. Nano Lett. https://doi.org/10.1021/n1005521zGoogle Scholar

- Tu Y, Lin Y, Yantasee W, Ren Z (2005) Carbon nanaotubes based nanoelectrode arrays: Fabrication, evaluation and application in voltammetric analysis. Electroanalysis. https://doi.org/10.1002/elan.200403122Google Scholar

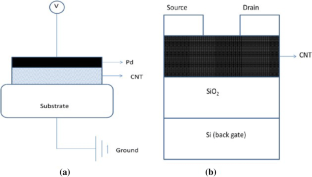

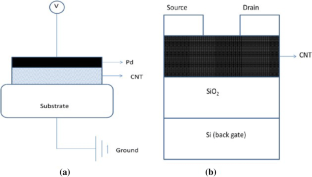

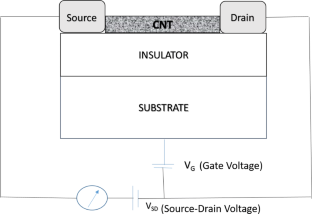

- Tans SJ, Verscheren ARM, Cees Dekker (1998) Room-temperature transistor based on a single carbon nanotube. Nature 383:49–52 Google Scholar

- Martel S et al (1998) Single- and multi-wall carbon nanotubes field-effect transistors. Appl Phys Lett 10(1063/1):122477 Google Scholar

- Kong J et al (2000) Nanotube molecular wires as chemical sensors. Science 287:622–625 Google Scholar

- Douglas KR, Star A (2008) Carbon nanotube gas and vapor sensors. Angew Chem Int Ed. https://doi.org/10.1002/anie.200704488Google Scholar

- Katz HE (2004) Chemically sensitive field-effect transistors and chemiresistors: new materials and device structures. Electroanalysis. https://doi.org/10.1002/elan.200403071Google Scholar

- Snow ES, Perkins FK, Robinson JA (2006) Chemical vapor detection using single-walled carbon nanotubes. Chem Soc Rev. https://doi.org/10.1039/b515473cGoogle Scholar

- Zhang T, Mubeen S, Myung NV, Deshusses MA (2008) Recent progress in carbon nanotubes-based gas sensors. Nanotechnology. https://doi.org/10.1088/0957-4484/19/33/332001Google Scholar

- Wang Y, Yeow JTW (2009) A review of carbon nanotubes-based gas sensors. J Sens. https://doi.org/10.1155/2009/493904Google Scholar

- Cantalini C et al (2004) Carbon nanotubes as new materials for gas sensing applications. J Eur Ceram Soc. https://doi.org/10.1016/s0955-2219(03)00441-2Google Scholar

- Modi A, Koratkar N, Lass E, Wei B, Ajayan PM (2003) Miniaturized gas ionization sensors using carbon nanotubes. Nature 424:171–174 Google Scholar

- Peng S, Cho K (2003) Ab initio study of doped carbon nanotube sensors. Nano Lett. https://doi.org/10.1021/n1034064uGoogle Scholar

- Villalpando-P’aez F et al (2004) Fabrication of vapor and gas sensors using films of aligned CNx nanotubes. Chem Phys Lett 10:10. https://doi.org/10.1016/j.cplett.2004.01.052Google Scholar

- Dag S et al (2005) Adsorption and dissociation of hydrogen molecules on bare and functionalized carbon nanotubes. Phys Rev B. https://doi.org/10.1103/physrevb.72.155404Google Scholar

- Kong J et al (2001) Functionalized carbon nanotubes for molecular hydrogen sensors. Adv Mater 13(18):1384–1386 Google Scholar

- Olsen RA et al (2004) Adosrption and diffusion on a stepped surface: atomic hydrogen on Pt (211). J Chem Phys. https://doi.org/10.1063/1.1755664Google Scholar

- Davis JJ et al (1997) Protein electrochemistry at carbon nanotube electrodes. J Electroanal Chem 440:279–282 Google Scholar

- Chen RJ et al (2001) Non-covalent sidewall functionalization of single-walled carbon nanotubes for protein immobilization. J Am Chem Soc. https://doi.org/10.1021/ja010172bGoogle Scholar

- Thess A et al (1996) Crystalline ropes of metallic carbon nanotubes. Science 273:483–487 Google Scholar

- Wang J et al (2003) Solubilization of Carbon Nanotubes by Nafion toward the Preparation of Amperometric Biosensors. J Am Chem Soc. https://doi.org/10.1021/ja028951vGoogle Scholar

- Brinda GC et al (1998) Carbon nanotubule membranes for electrochemical energy storage and production. Nature 393:346–349 Google Scholar

- Yu Y et al (2009) Assembly of multi-functional nanocomponents on periodic nanotube array for biosensors. Micro Nano Lett. https://doi.org/10.1049/mnl.20080054Google Scholar

- Musameh M, Wang J, Merkoci A, Lin Y (2002) Low-potential stable NADH detection at carbon-nanotube-modified glassy carbon electrodes. Electrochem Commun. https://doi.org/10.1016/s1388-2481(03)00076-6Google Scholar

- Yu X et al (2003) Peroxidase activity of enzymes bound to the ends of single-wall carbon nanotube forest electrodes. Electrochem Commun 5:408–411 Google Scholar

- Yanga N et al (2015) Carbon nanotube based biosensors. Sens Actuators B 207:690–715 Google Scholar

- Walters DA et al (1999) Elastic strain of freely suspended single-wall carbon nanotube ropes. Appl Phys Lett. https://doi.org/10.1063/1.124185Google Scholar

- Krishnan A et al (1998) Young’s modulus of single-walled nanotubes. Phys Rev B 58(20):14013–14019 Google Scholar

- Wong EW et al (1997) Nanobeam mechanics: elasticity, strength, and toughness of nanorods and nanotubes. Science 277:1971–1975 Google Scholar

- Treacy JMM et al (1996) Exceptionally high young’s modulus observed for individual carbon nanotubes. Nature 381:678–680 Google Scholar

- Yu MF et al (2000) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287:637–640 Google Scholar

- Bazbouz MB, Stylios GK (2008) Novel mechanism for spinning continuous twisted composite nanofiber yarns. Eur Polymer J. https://doi.org/10.1126/science.1104276Google Scholar

- Zhang M et al (2004) Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science. https://doi.org/10.1126/science.1104276Google Scholar

- Jiang K, Li Q, Fan S (2002) Spinning continuous carbon nanotube yarns. Nature 419:801 Google Scholar

- Wu Z (2004) Transparent, conductive carbon nanotube films. Science. https://doi.org/10.1126/science.1101243Google Scholar

- Liu K, Sun Y, Chen L, Feng C, Feng X, Jiang K, Zhao Y, Fan S (2008) Controlled growth of super-aligned carbon nanotube arrays for spinning continuous unidirectional sheets with tunable physical properties. Nano Lett. https://doi.org/10.1021/n10723073Google Scholar

- Postma HW, Teepen T, Yao Z, Grifoni M, Dekker C (2001) Carbon nanotube single-electron transistors at room temperature. Science. https://doi.org/10.1126/science.1061797Google Scholar

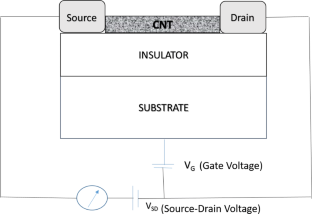

- Prakash P et al (2018) A review on carbon nanotube field effect transistors (CNTFETs) for ultra-low power applications. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2018.03.021Google Scholar

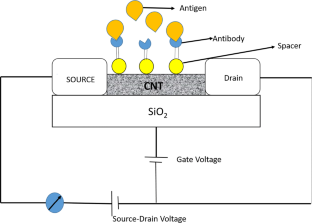

- Gruner G (2006) Carbon nanotube transistors for biosensing applications. Anal Bioanal Chem. https://doi.org/10.1007/s00216-005-3400-4Google Scholar

- Winter M, Brodd RJ (2004) What are batteries, fuel cells, and supercapacitors? Chem Rev. https://doi.org/10.1021/cr020730kGoogle Scholar

- Dai H, Wong EW, Liebert CM (1996) Probing electrical transport in nanomaterials: conductivity of individual carbon nanotubes. Science 272:523–526 Google Scholar

- Tang H et al (2004) High dispersion and electrocatalytic properties of platinum on well-aligned carbon nanotube arrays. Carbon. https://doi.org/10.1016/j.carbon.2003.10.023Google Scholar

- Ebbesen TW, Ajayan PM (1992) Large-scale synthesis of carbon nanotubes. Nature 358:220–222 Google Scholar

- Largeot C et al (2008) Relation between the ion size and pore size for an electric double-layer capacitor. J Am Chem Soc. https://doi.org/10.1021/ja7106178Google Scholar

- Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7:845–854 Google Scholar

- Zhang LL, Zhao XS (2009) Carbon-based materials as supercapacitor electrodes. Chem Soc Rev. https://doi.org/10.1039/b813846jGoogle Scholar

- Zhang H et al (2008) Tube-covering-tube nanostructured polyaniline/carbon nanotube array composite electrode with high capacitance and superior rate performance as well as good cycling stability. Electrochem Commun. https://doi.org/10.1016/j.elecom.2008.05.007Google Scholar

- Zhong DY et al (2001) Lithium storage in polymerized carbon nitride nanobells. Appl Phys Lett. https://doi.org/10.1063/1.1419034Google Scholar

- Baughman RH et al (1999) Carbon nanotube actuators. Science. https://doi.org/10.1126/science.284.5418.1340Google Scholar

- Urban J, Jandera P (2008) Polymethacrylate monolithic columns for capillary liquid chromatography. J Sep Sci 31(14):2521–2540. https://doi.org/10.1002/jssc.200800182Google Scholar

- Svec F (2010) Porous polymer monoliths: amazingly wide variety of techniques enabling their preparation. J Chromatogr A 1217(6):902–924. https://doi.org/10.1016/j.chroma.2009.09.073Google Scholar

- Lu H, Chen G (2011) Recent advances of enantioseparations in capillary electrophoresis and capillary electrochromatography. Anal Methods 3(3):488. https://doi.org/10.1039/c0ay00489hGoogle Scholar

- Moliner-Martínez Y, Barrios M, Cárdenas S, Valcárcel M (2008) Comparative study of carbon nanotubes and C60 fullerenes as pseudostationary phases in electrokinetic chromatography. J Chromatogr A 1194(1):128–133. https://doi.org/10.1016/j.chroma.2008.04.034Google Scholar

- ALOthman ZA, Wabaidur SM (2018) Application of carbon nanotubes in extraction and chromatographic analysis: a review. Arab J Chem. https://doi.org/10.1016/j.arabjc.2018.05.012Google Scholar

- Fadhillahanafi NM, Leon KY, Risby MS (2013) Stability and thermal conductivity characteristics of carbon nanotube based nanofluids. Int J Automot Mech Eng (IJAME). https://doi.org/10.1016/j.arabjc.2018.05.012Google Scholar

- Kumaresan V, Velraj R (2012) Experimental investigation of the thermo-physical properties of water–ethylene glycol mixture based CNT nanofluids. Thermochim Acta 545:180–186. https://doi.org/10.1016/j.tca.2012.07.017Google Scholar

- Harish S, Ishikawa K, Einarsson E, Aikawa S, Chiashi S, Shiomi J, Maruyama S (2012) Enhanced thermal conductivity of ethylene glycol with single-walled carbon nanotube inclusions. Int J Heat Mass Transf 55(13–14):3885–3890. https://doi.org/10.1016/j.ijheatmasstransfer.2012.03.001Google Scholar

- Ghozatloo A, Rashidi AM, Shariaty-Niasar M (2014) Effects of surface modification on the dispersion and thermal conductivity of CNT/water nanofluids. Int Commun Heat Mass Transf 54:1–7. https://doi.org/10.1016/j.icheatmasstransfer.2014.02.013Google Scholar

- Walvekar R, Siddiqui MK, Ong S, Ismail AF (2015) Application of CNT nanofluids in a turbulent flow heat exchanger. J Exp Nanosci 11(1):1–17. https://doi.org/10.1080/17458080.2015.1015461Google Scholar

- Venkatesan SP, Hemanandh J (2018) Experimental investigation on convective heat transfer coefficient of water/ethylene glycol-carbon nanotube nanofluids. Int J Ambient Energy. https://doi.org/10.1080/01430750.2018.1472649Google Scholar

- Sharma B, Sharma SK, Gupta SM, Kumar A (2018) Modified two-step method to prepare long-term stable CNT nanofluids for heat transfer applications. Arab J Sci Eng 10:10. https://doi.org/10.1007/s13369-018-3345-5Google Scholar

- Sharma SK, Gupta SM (2016) Preparation and evaluation of stable nanofluids for heat transfer application: a review. Exp Thermal Fluid Sci 79:202–212. https://doi.org/10.1016/j.expthermflusci.2016.06.029Google Scholar

- Sharma SK, Gupta SM (2018) Synergic effect of SDBS and GA to prepare stable dispersion of CNT in water for industrial heat transfer applications. Mater Res Express 5(5):055511. https://doi.org/10.1088/2053-1591/aac579Google Scholar

- Babita Sharma S K, Gupta SM, Kumar A (2018) A effect of surfactant on CNT dispersion in polar media and thermal conductivity of prepared CNT nanofluids. ARPN J Eng Appl Sci 13(4):1202–1211 Google Scholar

Acknowledgements

This study is financially supported by GGSIP University, Dwarka under FRGS Project.

Funding

The study was supported by FRGS grant from GGSIPU, Dwarka, New Delhi, India.

Author information

Authors and Affiliations

- USBAS, Guru Gobind Singh Indraprastha University, Dwarka, New Delhi, 110078, India Nikita Gupta & Shipra Mital Gupta

- USCT, Guru Gobind Singh Indraprastha University, Dwarka, New Delhi, 110078, India S. K. Sharma

- Nikita Gupta